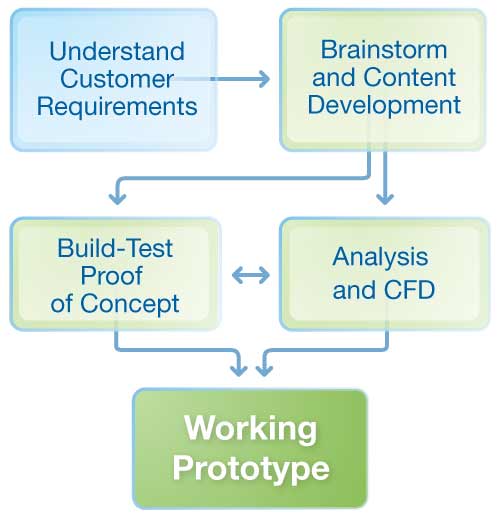

First our engineers use rigorous analysis to understand how a device works, and to predict how a new concept might work better. Whether we are designing a new rocket nozzle, a medical device pump or an industrial compressor, we create a theoretical model of the device and validate it. The theoretical model may be a CFD simulation or a detailed mathematical model. Once we have an analysis that looks correct, we make sure that our model fits a known device. We do this by an extensive search of journal articles/technical papers for similar devices, or by comparing via laboratory testing to a similar device (many of which we have in stock in our lab). We have the experience and the know-how to develop analysis methods that can be trusted. Once we know how accurate our analysis is, we can use it to predict the behavior of new concepts before building and testing them. We use this type of methodology to test out potential solutions quickly and reject those that won’t meet specifications. These results are then used to aid in mechanical design and fabricated prototypes and/or working parts.

Example

For example, while developing a gas temperature control system for a customer, we developed a model of the system including the gas, the heat exchanger tube and fins, the water and the metal enclosure walls. This allowed us to predict the temperature response of the system when subjected to a transient heat input. The model predicts the temperature accurately and it was used to help program the control system for the heat exchanger to keep the system at a constant temperature. All this was done before a single piece of metal was cut!